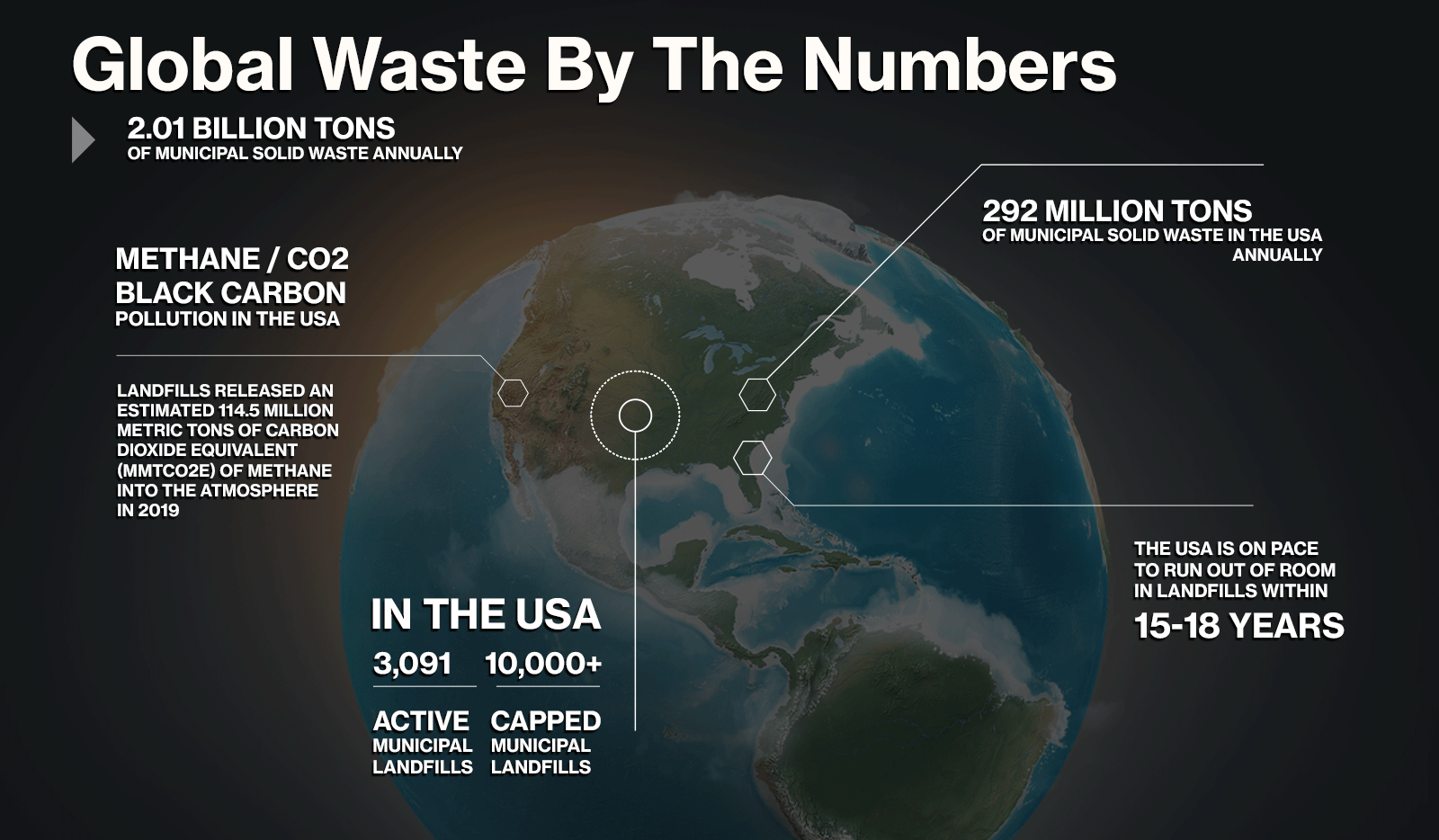

WASTE IS A MASSIVE GROWING PROBLEM

The three main problems with landfill are toxins, leachate and greenhouse gases. When organic material such as food scraps and green waste is put in a landfill, it is generally compacted down and covered. This removes the oxygen and causes it to break down in an anaerobic process. Eventually this releases methane, a greenhouse gas that is about 25 times more potent than carbon dioxide. Landfill gas comprises 35-55% methane and 30-44% carbon dioxide.

Methane is also a flammable gas that can become dangerous if allowed to build up in concentration. The implications for global warming and climate change are enormous. The most pressing environmental concern regarding landfills is their release of methane gas. As the organic mass in landfills decompose methane gas is released. This can also result in leachate, a liquid produced by landfill sites, contaminating nearby water sources, further damaging ecosystems.

The United States has over 3,000 active landfills and 10,000 closed landfills. Methane is 84 times more effective at absorbing the sun’s heat than carbon dioxide, making it one of the most potent greenhouse gases and a huge contributor to climate change.

Synthetic Fuels

There is exponentially increasing demand for clean synthetic fuels for the airline industry and other markets. The global aviation fuel market alone is expected to increase to over $500B in 2050.

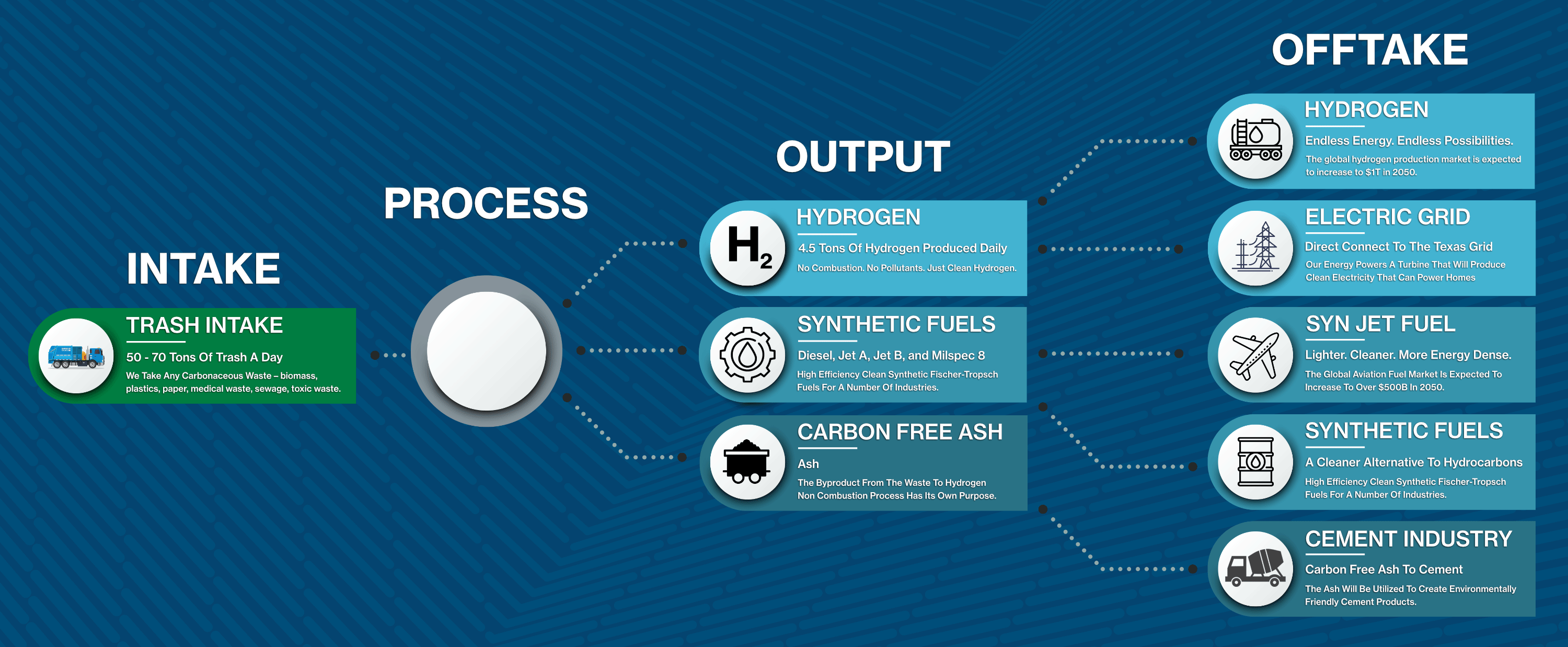

Our facility can process 50-70 tons of waste a day. Due to the unique nature of the technology we are able to process “wet” materials which means less energy used to dry the material before we are able to process it. Although removing plastics, tires and medical waste are the desired feedstock to use based on the level of pollutants they create, we are also able to process food waste. (A major contributor to methane buildup in landfills).

Our goal is to utilize emerging technology to find the best (and most practical) solutions to creating and storing hydrogen in an efficient manner. The technology partners we have chosen for this project have an exceptional track record when it comes to transforming landfill waste into hydrogen. The key benefit of our technology is that there is NO combustion required to produce the hydrogen. The current waste to energy model requires trash to be burned in order to create energy. This methodology is inefficient and releases a number of highly dangerous pollutants into the atmosphere.

Our Technology transforms waste into clean fuels, uses less electricity to produce, doesn’t need “clean” water to operate, removes carbon from the atmosphere, has fewer process emissions since its non-combustion, and avoids CO2e (methane) emissions by removing waste from landfills. Simply put… This is one of the most environmentally friendly ways to produce hydrogen with the massive added benefit of cleaning up our landfills at the same time.

We have the ability to create an exceptionally pure hydrogen though the steam reforming process. No combustion. No pollutants. Just clean hydrogen.

The operational capabilities of our systems also makes sustainable, clean burning synthetic jet fuel for the aviation industry.

An interesting thing occurs when we process the waste through our system. The properties of the residual ash that is created from the system once it is done processing and converting the waste to hydrogen is a prime candidate to help cement plants reduce their carbon footprint.

Based on rough estimates, 50-70 tons of trash will net 4.5 tons (4000+kg) of pure hydrogen/synthetic Fischer-Tropsch fuels a day. The flexibility of our system will allow us to determine what we produce. This will allow us the opportunity to target a number of industries that require clean fuels to operate.

We will solve four problems with our system: